High Quality Crusher Jaw Plate Supplier from China

A crusher jaw plate is a replaceable component that comes in contact with raw materials in the crushing chamber of a jaw crusher. The jaw plates are usually mounted in pairs — one fixed and one moveable. During the crushing process, the movable plate moves back and forth against the fixed plate, crushing the rock in between.

Jaw plates are crucial wear parts in the jaw crusher, and their durability determines the machine’s lifespan and productivity. If your operation involves frequent crushing of abrasive materials, it’s vital to use high-strength, wear-resistant jaw plates for maximum efficiency.

Crusher jaw plates are one of the most essential components of jaw crushers, widely used in mining, quarrying, construction, recycling, and demolition industries. These plates are the primary wear parts of a jaw crusher, responsible for crushing hard materials such as granite, basalt, limestone, and concrete. Choosing the right jaw plate not only ensures crushing efficiency but also significantly improves the service life of your crusher equipment.

At Econe, we specialize in manufacturing and exporting high-quality crusher jaw plates for all major jaw crusher brands. Our wear parts are made from premium manganese steel, alloy steel, and customized materials according to customer specifications. Whether you are looking for high manganese jaw plates, custom-designed jaw plates, or standard OEM replacement jaw plates, we provide reliable solutions with competitive prices and fast delivery.

Key Specifications of Crusher Jaw Plates

- Material Options: High-Manganese Steel, Alloy Steel, or Custom Alloys

- Hardness: ≥ HRC 50

- Impact Toughness: ≥ 15 J/cm²

- Wear Resistance: ≥ 30-40 g/ton

- Design: Standard and custom design options available

- Weight Range: From 1 kg to 50 tons

- Tolerance: ±1mm

- Surface Finish: Precision-cast for superior wear performance

- Application: Cement, mining, construction, and aggregate processing industries

Advantages of Econe Cement’s Crusher Jaw Plates

High Wear Resistance:

Our crusher jaw plates are made from high-manganese steel or alloy steel, offering superior resistance to wear and tear, making them perfect for high-impact and abrasive environments.Longer Lifespan:

Engineered for longevity, our jaw plates are designed to extend the lifespan of your crushers, reducing the frequency of replacements and minimizing downtime.Improved Crushing Efficiency:

The precise design of our crusher jaw plates ensures efficient material processing and a consistent reduction ratio, enhancing the overall performance of your crushing system.Customizable Designs:

We offer customized jaw plates that meet your specific crushing requirements, whether for small or large-scale operations, ensuring optimal performance and a perfect fit for your crushers.Cost-Effective Solutions:

With our durable and high-performance crusher jaw plates, you’ll experience reduced maintenance costs, higher operational uptime, and overall cost efficiency in your crushing operations.Eco-Friendly Manufacturing:

We use sustainable materials and environmentally friendly production processes, ensuring our crusher jaw plates comply with global environmental standards.

Applications of Crusher Jaw Plates

Econe Cement’s crusher jaw plates are suitable for a wide range of industries where material crushing is essential, including:

Cement Plants:

Our jaw plates are essential for crushers in cement production, where they help crush raw materials such as limestone, clay, and gypsum.Mining Industry:

Ideal for primary and secondary crushers in mineral processing, our jaw plates efficiently crush ores, rocks, and other hard materials.Construction and Aggregates:

Our crusher jaw plates are used in aggregate plants to process rocks and other materials, ensuring consistent output and optimal processing efficiency.Recycling Industry:

Used in crushers to process construction waste, concrete, and other recyclable materials, ensuring efficient reduction and recycling.

Why Choose Econe Cement for Your Crusher Jaw Plate Needs?

Expert Manufacturer:

With years of experience in manufacturing crusher parts, we specialize in providing durable and efficient jaw plates for cement, mining, and aggregate industries worldwide.Customization to Your Needs:

We offer customized crusher jaw plates designed to meet your specific crushing and material processing needs, ensuring the best possible performance.Premium Materials and Manufacturing:

Our jaw plates are made from the highest-grade materials, ensuring they stand up to the most demanding conditions and provide superior wear resistance and performance.Global Shipping and Support:

Econe Cement serves customers worldwide, offering fast shipping, reliable support, and installation assistance to ensure the best possible experience with our products.Competitive Pricing:

We provide high-quality crusher jaw plates at competitive prices, helping you reduce operating costs and improve productivity.

Certifications and Quality Assurance

At Econe Cement, we ensure that all our crusher jaw plates meet the highest international quality standards. Our products are certified with:

- ISO 9001:2015 – Quality Management System

- ISO 14001:2015 – Environmental Management System

- OHSAS 18001 – Occupational Health and Safety Management

- CE Certification – Compliance with European Union safety standards

Our rigorous quality control procedures guarantee that every jaw plate performs reliably in even the harshest operating conditions.

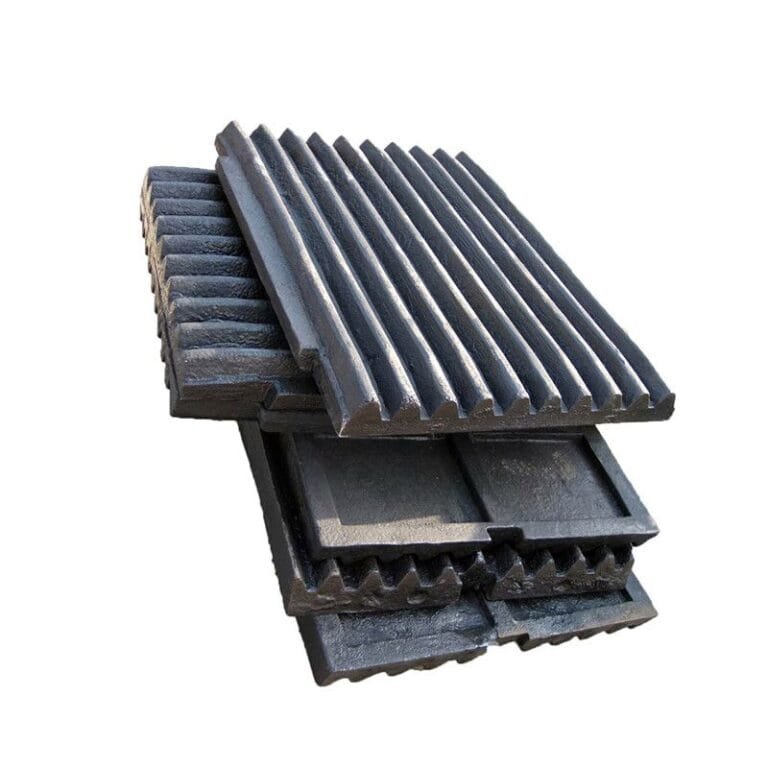

Jaw Plate Types and Designs

We offer several types of jaw plates to suit different crushing applications:

a. Standard Tooth Jaw Plates

Most commonly used type.

Suitable for crushing soft to medium-hard materials.

Provides a balance of wear life and crushing performance.

b. Heavy-Duty Tooth Jaw Plates

Thicker and deeper tooth profiles.

Ideal for high-impact and large feed size applications.

Extended service life in extreme working conditions.

c. Reversible Jaw Plates

Both sides can be used interchangeably.

Maximizes the usage life of each jaw plate.

Reduces downtime and maintenance cost.

d. Corrugated Jaw Plates

Designed for better grip on feed material.

Effective in wet or sticky material applications.

Increases material throughput and reduces slippage.

e. Wavy Jaw Plates

Promotes aggressive crushing action.

Used in applications requiring high output and fine crushing.

f. Custom Jaw Plates

Designed based on customer drawings or specifications.

Tailored hardness, thickness, and geometry.

Compatible with all major brands (e.g., Metso, Sandvik, Terex, Kleemann, etc.).

Materials Used in Jaw Plates

Material composition plays a key role in the performance of jaw crusher wear parts. We offer the following materials for our jaw plates:

a. High Manganese Steel (Mn13, Mn18, Mn22)

Industry-standard material for jaw plates.

Self-hardening property: becomes harder under pressure and wear.

Excellent toughness and work-hardening capabilities.

Cost-effective and durable.

b. Alloy Steel

Offers better wear resistance in extreme environments.

Suitable for applications with high impact or abrasive feed.

Enhanced mechanical properties due to alloying elements.

c. Bimetallic Composite

Combines the wear resistance of hard metal and the toughness of base steel.

Ideal for heavy-duty mining applications.

d. Customized Materials

Chromium, molybdenum, vanadium, or other trace elements.

Designed for specific mineral processing requirements.

8. Advantages of Our Crusher Jaw Plates

Competitive Pricing: Direct factory supply with no middlemen.

Customized Solutions: Tailor-made for your specific crusher brand and model.

Fast Delivery: Large stock and short lead times.

Consistent Quality: Strict inspection and quality control standards.

Global Export Experience: Shipped to over 60 countries.

Technical Support: Guidance for installation, maintenance, and wear analysis.

OEM Compatibility: Compatible with Metso, Sandvik, Terex, and other brands.

9. Jaw Plate Installation & Maintenance

Proper installation and timely maintenance of your jaw plates will ensure the maximum lifespan. Here are some tips:

Always replace both jaw plates together.

Check for loose bolts and fixings regularly.

Rotate reversible jaw plates at scheduled intervals.

Use anti-seize lubricant during installation.

Monitor wear patterns and plan replacements in advance.

We also provide a free user guide and maintenance tips with every shipment.

10. OEM & Customization Services

We provide full OEM & ODM services:

Custom jaw plate shapes and dimensions.

Branding and logo engraving.

Special surface coatings and treatments.

Material selection consulting.

3D CAD modeling for customer design verification.

If you have special requirements, send us your drawings or samples, and we’ll produce exact-fit replacement parts.

11. Packaging & Shipping

Packaging: Export-standard wooden cases or steel pallets.

Protection: Anti-corrosion wrapping and shock-absorbing fillers.

Shipping: By sea, air, or express (DHL/FedEx/UPS).

Lead Time: 7–25 days depending on order size.

We handle all export documents and customs clearance.

Why Choose Us as Your Jaw Plate Supplier?

✅ Over 15 Years of Manufacturing Experience

✅ Strict Quality Assurance & Material Testing

✅ ISO & CE Certified Production Facility

✅ Rapid Prototyping & Mass Production Capability

✅ Strong R&D and Engineering Team

✅ Competitive Wholesale Pricing

✅ Global Shipping & After-Sales Support

Customer Testimonials

“We’ve tried several suppliers over the years, and [Your Company Name] consistently delivers jaw plates with excellent wear life and fast turnaround. Highly recommended!”

— David M., Quarry Manager, USA

“Customized jaw plates for our Sandvik crusher fit perfectly and lasted 20% longer than OEM parts. Great value for money.”

— Andreas H., Germany

Global Export Markets

Our crusher jaw plates are exported to the following regions:

North America (USA, Canada, Mexico)

Europe (Germany, UK, France, Italy)

Southeast Asia (Vietnam, Thailand, Philippines)

Middle East (UAE, Saudi Arabia, Iran)

Africa (South Africa, Nigeria, Egypt)

Latin America (Brazil, Peru, Chile)

Australia and New Zealand

FAQs About Crusher Jaw Plates

Q: How long does a jaw plate last?

A: Depending on material type and usage conditions, jaw plates can last between 40 to 120 operating hours or more.

Q: Can I get a sample before bulk order?

A: Yes, sample orders are available upon request.

Q: How do I choose the right jaw plate for my crusher?

A: Our engineers will recommend the best jaw plate based on your crusher model, feed size, and operating conditions.

Q: Do you offer technical support?

A: Yes, we provide full technical support before and after sales.

Get a Quote

Ready to improve your crusher’s efficiency and reduce maintenance costs?

📞 Contact us now for a free consultation and price quote!

📧 Email: john@cementplantpart.com

Whatsapp: 0086-15057941949

🌐 Website: www.cementplantpart.com

Blog & News

How to Buy Cheap Cone Crusher Wear Parts for Your Cone Crusher