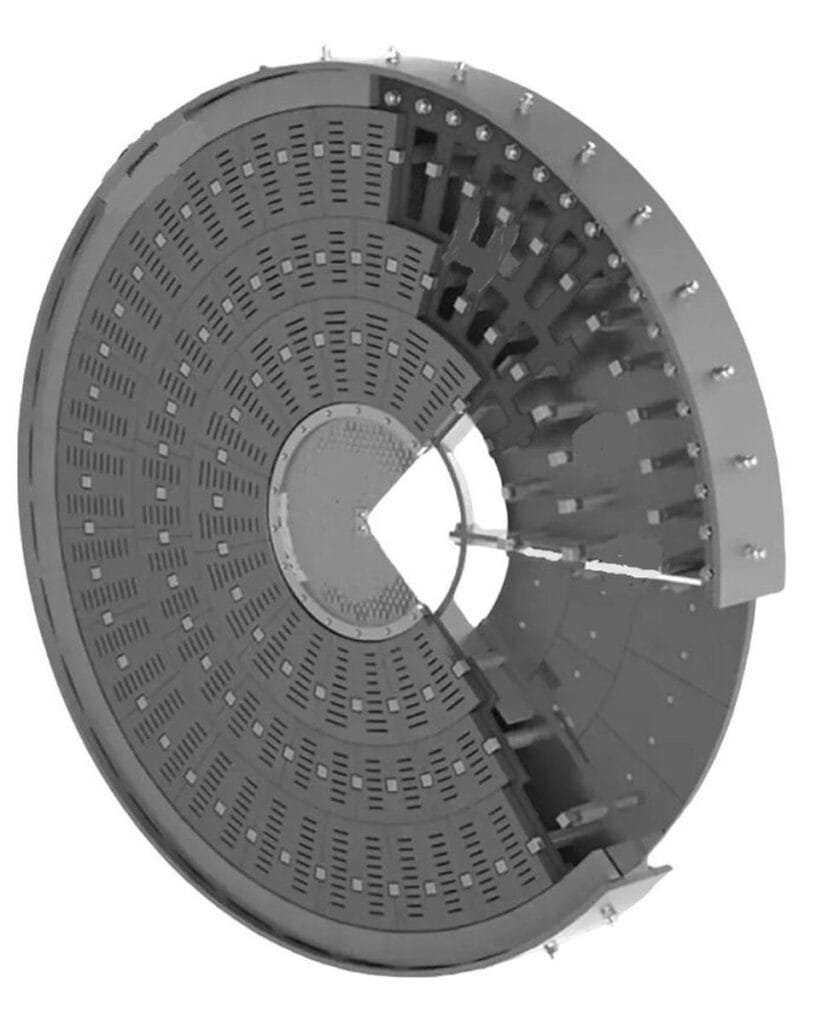

Custom Ball Mill Diaphragm

- Customized Ball Mill Diaphragm – Wear Parts Manufacturer

- Material: High Manganese Steel (Mn13, Mn18Cr2), High Chromium Cast Iron (Cr15, Cr20, Cr26), Alloy Steel (ZG40CrMo, ZG45Mn)

- Hardness: 45-65 HRC (Rockwell hardness scale)

- Weight: 5 kg – 500 kg (customized based on the mill size and design)

- Applications: Cement Industry (for raw material and clinker grinding), Mining Industry (ore and mineral grinding), Power Plants (coal mills), Chemical Industry (chemical material grinding), Metallurgical Industry (metal extraction)

- Customizable: Yes, liners can be customized in terms of size, material composition, and design to fit specific customer requirements.

Casting ball mill diaphragm Overview

Econe Cement, a trusted Ball Mill Diaphragm supplier and manufacturer, specializes in custom high-performance ball mill diaphragms designed for use in cement and industrial grinding mills. Our ball mill diaphragms are crucial components that separate the different chambers of the ball mill, helping to control the material flow and optimizing the grinding process.

Manufactured from high-quality materials such as high-chrome cast iron and alloy steel, our diaphragms offer exceptional durability and wear resistance. Designed to improve grinding efficiency and extend the lifespan of your grinding equipment, Econe Cement’s ball mill diaphragms are engineered to meet the demanding conditions of modern cement mills and other industrial applications.

Key Specifications of custom Ball Mill Diaphragms

- Material Options: High-Chrome Cast Iron, Alloy Steel, Custom Alloys

- Hardness: ≥ HRC 50

- Impact Toughness: ≥ 15 J/cm²

- Wear Resistance: ≥ 30-40 g/ton

- Design: Fixed and adjustable configurations for different mill types

- Tolerance: ±1mm

- Weight Range: From 0.1 to 50 tons

- Surface Finish: Precision-cast for smooth wear performance

- Application: Cement grinding, mining, and industrial grinding processes

Advantages of Econe Cement’s Ball Mill Diaphragms

Enhanced Grinding Efficiency:

Our ball mill diaphragms are designed to optimize the material flow between the mill chambers, improving grinding efficiency and ensuring a better distribution of materials for consistent grinding results.Durable and Wear-Resistant:

Made from high-chrome cast iron or alloy steel, Econe Cement’s ball mill diaphragms provide superior resistance to wear, reducing the need for frequent replacements and minimizing downtime.Customizable Design:

We offer customized ball mill diaphragms that meet the unique specifications and requirements of your cement mill, ensuring an optimal fit and performance for various mill types and sizes.Extended Equipment Lifespan:

With our robust diaphragms, the service life of your ball mills is extended, resulting in fewer replacements and less maintenance, thereby reducing long-term operational costs.Cost-Effective Maintenance:

By improving the grinding process and extending the life of your equipment, our ball mill diaphragms help reduce maintenance costs, enhance productivity, and improve cost efficiency.Quick and Easy Installation:

Our diaphragms are designed for easy installation and replacement, minimizing downtime during maintenance and keeping your operations running smoothly.

Applications of Ball Mill Diaphragms

Econe Cement’s ball mill diaphragms are ideal for various industries, particularly those focused on grinding and material processing, including:

Cement Plants:

Ball mill diaphragms improve the grinding efficiency in cement mills, helping to optimize material flow, increase output, and reduce energy consumption.Mining Industry:

Used in mineral processing mills, our diaphragms ensure efficient grinding and separation of materials, improving throughput and reducing operational costs.Power Generation:

In power plants, our diaphragms are used in coal mills and other grinding systems, optimizing grinding efficiency and reducing energy consumption.Chemical & Pharmaceutical Industries:

Ball mill diaphragms play a crucial role in controlling the grinding process, making them ideal for industries that require precision in material grinding and processing.

Why Choose Econe Cement for Your Ball Mill Diaphragm Needs?

Industry Expertise:

Econe Cement is a trusted supplier with years of experience in manufacturing high-quality ball mill diaphragms and other essential components for cement plants and industrial mills.Customized Solutions:

We work closely with clients to design ball mill diaphragms that fit their specific mill types and operational requirements, ensuring the best possible performance.Premium Materials:

Our ball mill diaphragms are made from top-grade materials such as high-chrome cast iron and alloy steel, ensuring exceptional durability, strength, and resistance to wear and tear.Global Reach and Service:

As a global supplier, Econe Cement provides international shipping and after-sales support, ensuring that your products arrive on time and in optimal condition.Competitive Pricing:

We offer cost-effective solutions that deliver value for money, ensuring you get the most efficient and durable ball mill diaphragms at competitive prices.

Certifications and Quality Assurance

Econe Cement’s ball mill diaphragms meet the highest international quality standards. Our products are certified with:

- ISO 9001:2015 – Quality Management System

- ISO 14001:2015 – Environmental Management System

- OHSAS 18001 – Occupational Health and Safety Management

- CE Certification – Compliance with European Union safety standards

We ensure that every product undergoes rigorous quality control processes to meet the highest standards for performance, safety, and reliability.

Get in Touch with Econe Cement – Your Trusted Ball Mill Diaphragm Supplier

To learn more about our ball mill diaphragms or to receive a customized quote, contact Econe Cement today!

Blog & News

Selection and Replacement of Ball Mill Liner and Grinding Balls

Why Custom Ball Mill Liners Are Critical for Unique Applications

How to Choose Best Ball Mill Liner Materials in Cement Industry

Key Considerations for Ball Mill Liner Replacement in Cement Plant

Why Ball Mill Liner Quality Is Crucial for Long-Term Productivity