Ball Mill Spare Parts - High Quality Wear Resistant Part for Sale

High Quality Ball Mill Spare Parts Supplier – Customized Wear resistant Parts Manufacturer From China

- Material: High Manganese Steel (Mn13, Mn18Cr2), High Chromium Cast Iron (Cr15, Cr20, Cr26), Alloy Steel (ZG40CrMo, ZG45Mn)

- Hardness: 45-65 HRC (Rockwell hardness scale)

- Weight: 5 kg – 500 kg (customized based on the mill size and design)

- Applications: Cement Industry (for raw material and clinker grinding), Mining Industry (ore and mineral grinding), Power Plants (coal mills), Chemical Industry (chemical material grinding), Metallurgical Industry (metal extraction)

- Customizable: Yes, liners can be customized in terms of size, material composition, and design to fit specific customer requirements.

- Material: High-grade rubber with excellent elasticity and abrasion resistance

- Thickness Range: 40 mm – 100 mm (customizable as per mill requirements)

- Hardness: 65-75 Shore A (optimized for durability and flexibility)

- Liner Types: Shell liners, end liners, and lifter bars

- Weight: Lightweight compared to steel liners, reducing mill load

- Service Life: 1.5 – 2 times longer than traditional liners in most applications

- Customization: Available in various designs and configurations to suit specific mill models and applications

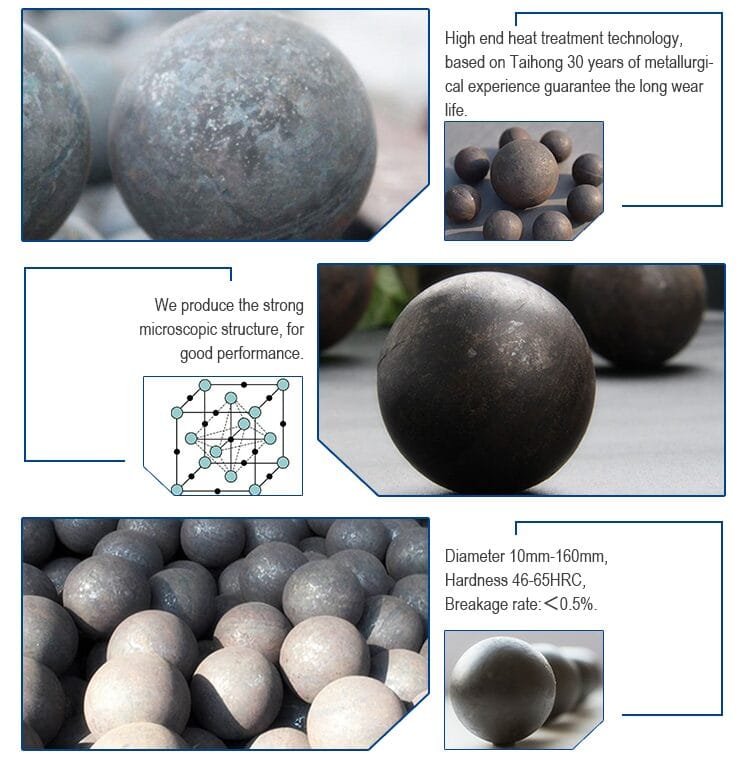

- Material: High Chromium Steel (Cr10, Cr15, Cr18), Forged Steel (B2, B3), Alloy Steel (ZGCr5Mo, ZGCr15)

- Hardness: 55-65 HRC (Rockwell hardness scale)

- Weight: 0.1 kg – 10 kg (varies based on size and specification)

- Applications: Cement Industry (raw material and clinker grinding), Mining Industry (ore and mineral processing), Power Plants (coal grinding), Chemical Industry (grinding chemicals and pigments)

- Customizable: Yes, we offer custom sizes and materials based on customer specifications and operational requirements.

- Material: High Manganese Steel (Mn13, Mn18Cr2), High Chromium Cast Iron (Cr15, Cr20, Cr26), Alloy Steel (ZG40CrMo, ZG45Mn)

- Hardness: 45-65 HRC (Rockwell hardness scale)

- Weight: 5 kg – 500 kg (customized based on the mill size and design)

- Applications: Cement Industry (for raw material and clinker grinding), Mining Industry (ore and mineral grinding), Power Plants (coal mills), Chemical Industry (chemical material grinding), Metallurgical Industry (metal extraction)

- Customizable: Yes, liners can be customized in terms of size, material composition, and design to fit specific customer requirements.

Ball Mill Trunnion - High Quality Parts

- Material: High Manganese Steel (Mn13, Mn18Cr2), Alloy Steel (ZG40CrMo, ZG45Mn), Cast Steel

- Hardness: 50-60 HRC (Rockwell hardness scale)

- Weight: 50 kg – 5000 kg (depending on mill size and design)

- Applications: Cement Industry (supporting ball mill rotation), Mining Industry (for ore grinding mills), Power Plants (coal mill trunnions), Metallurgical Industry (ball mill trunnions for mineral processing)

- Customizable: Yes, trunnions can be customized in size, material, and design to meet specific customer requirements and mill specifications

Ball Mill Girth Gear - Ball Mill Spare Parts

Material: High Carbon Steel (20CrMnTi, 40Cr, ZG45), Alloy Steel (ZG35, ZG35CrMo), Cast Steel

Hardness: Surface : 50-60 HRC (Rockwell hardness scale), Core: 30-40 HRC

Weight: Typically ranges from 500 kg to 30,000 kg

Diameter: typically ranging from 1m to 6m.

Tooth Profile: Available in different tooth profiles, such as helical, double helical, or straight tooth depending on the application and operational requirements.

Applications: Cement Industry (for rotation of grinding mills and kilns), Mining Industry (for ore and mineral grinding mills), Power Plants (used in coal mills and other large grinding equipment)

Ball Mill Spare Parts for Cement Plants & Mining Industry

we offer an extensive range of ball mill spare parts designed for the cement plant, mining, and other heavy industries. Our products are engineered for optimal performance, longevity, and reduced maintenance costs, ensuring that your operations run smoothly.

Key Ball Mill Spare Parts:

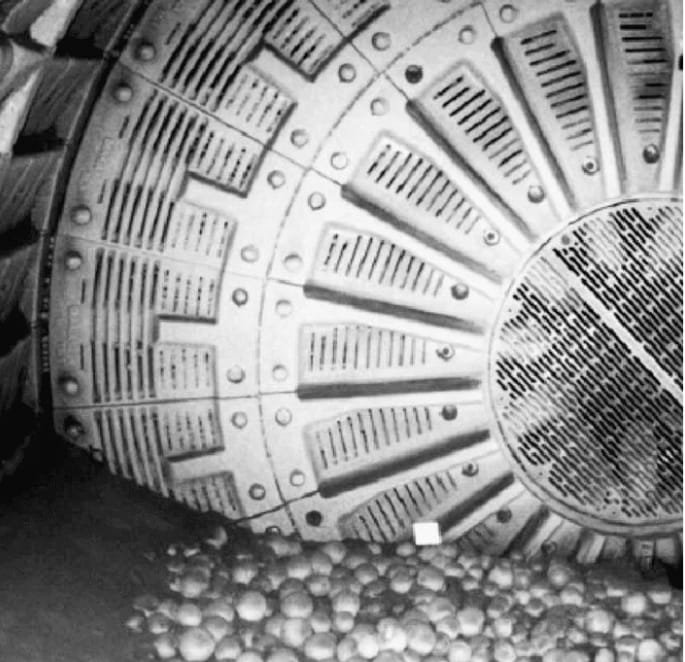

- Ball Mill Liners: Crafted from high-quality materials, our ball mill liners are designed for maximum wear resistance, enhancing your mill’s efficiency.

- Grinding Media (Steel Balls): We supply a wide range of steel balls used for grinding, ensuring superior grinding quality and durability.

- Cement Mill Parts: Offering various parts like shell liners, end liners, and diaphragms to maintain consistent mill performance.

- Trunnion Bearings & Support: Providing essential structural support and ensuring smooth and efficient operation of your ball mill.

- Seals & Gaskets: Protects your mill from leakage and ensures optimal operation by minimizing downtime.

Why Choose Our Ball Mill Spare Parts?

- Premium Quality Materials: We use high-quality steel, alloys, and castings that ensure the longevity and reliability of your equipment.

- Tailored Solutions: Our spare parts are custom-designed to fit various makes and models of ball mills.

- Cost-Effective: With a focus on durability, our products help reduce maintenance costs and improve overall plant efficiency.

- Expertly Manufactured: Every part is manufactured using advanced technology, ensuring high precision and performance.

- Global Shipping: We deliver worldwide with fast lead times, ensuring minimal downtime for your plant operations.

Trusted by Industry Leaders

With years of expertise and a reputation for excellence, ECONE is trusted by major players in the cement and mining industries globally. Our ball mill spare parts are tested to meet international standards, ensuring you get the best performance and value for your investment.

Contact Us Today

Looking for reliable ball mill spare parts? Contact us now for a quote or to learn more about how we can help optimize your milling operations.

Blog & News

Selection and Replacement of Ball Mill Liner and Grinding Balls

Why Custom Ball Mill Liners Are Critical for Unique Applications

How to Choose Best Ball Mill Liner Materials in Cement Industry

Key Considerations for Ball Mill Liner Replacement in Cement Plant

Why Ball Mill Liner Quality Is Crucial for Long-Term Productivity