In the world of crushing operations, choosing the right impact crusher blow bars is essential to maximize efficiency, reduce downtime, and enhance product quality. While standard blow bars meet general requirements, custom impact crusher blow bars tailored to specific applications can significantly improve operational outcomes.

Why Custom Blow Bars Matter

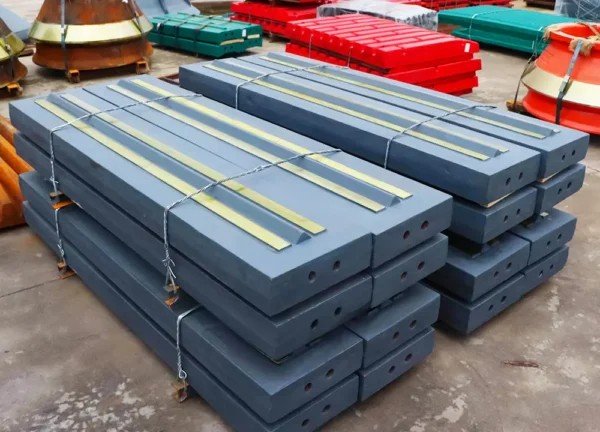

Impact crusher blow bars are wear parts responsible for crushing material in impact crushers. The performance of these components directly affects the crusher’s efficiency and maintenance costs. Standard blow bars are manufactured for average conditions, but many industries deal with unique material properties, environmental challenges, and production goals. This is where custom crusher blow bars come in.

Key Benefits of Custom Impact Crusher Blow Bars

Optimized Material Composition

Custom crusher blow bars can be made from high manganese steel, martensitic steel, chromium white iron, or even hybrid combinations. Choosing the right material for your specific feed material—be it limestone, granite, concrete, or asphalt—ensures longer wear life and consistent performance.Improved Wear Resistance

Tailored solutions offer better resistance to abrasive or high-impact materials. For example, chrome ceramic blow bars are ideal for asphalt recycling due to their high hardness and excellent wear resistance.Enhanced Crusher Compatibility

Custom crusher blow bars are engineered to match the geometry and mechanical constraints of your specific crusher model, improving fit, balance, and operational stability.Reduced Downtime and Maintenance Costs

With materials and profiles designed to withstand your operational environment, custom blow bars reduce wear rates and extend replacement intervals. This leads to lower maintenance frequency and associated labor costs.

Applications Where Custom Crusher Blow Bars Excel

Recycling Industry: Crushing reinforced concrete, demolition debris, and recycled asphalt requires specially engineered bars with excellent toughness and impact resistance.

Mining Operations: Processing abrasive ores demands blow bars with maximum hardness and structural integrity.

Çimento Fabrikaları: High-throughput environments benefit from custom designs that resist both wear and thermal shock.

Aggregates and Quarrying: Optimized profiles improve crushing efficiency for various rock types.

Choosing the Right Custom Crusher Blow Bar Manufacturer

To ensure your custom blow bars deliver optimal results, partner with a manufacturer who:

Offers a variety of material grades and casting methods

Understands your application and machine model

Provides precision machining and quality control

Delivers after-sales support, including wear analysis and performance optimization

Econe Industry Co., Ltd., for example, offers tailored solutions based on real-world testing and decades of industry expertise.

Final Thoughts

Yatırım yapmak custom impact crusher blow bars for specific crushing applications is a strategic move toward improving crusher performance, extending part life, and lowering operational costs. While the initial investment may be higher than standard parts, the long-term benefits in uptime and productivity make custom solutions the smart choice.