Rock Crusher Manufacturer in China

Welcome to Econe, a leading rock crusher manufacturer committed to providing high-quality, high-performance crushing equipment for global mining, quarrying, aggregate, and construction industries. With years of experience in manufacturing and exporting jaw crushers, hammer crushers, cone crushers, and impact crushers, we help customers worldwide achieve efficient material processing, reduced operational costs, and improved productivity.

Whether you’re crushing granite in a quarry, processing river stone in a concrete plant, or breaking down limestone for cement production, our full range of rock crushers ensures you find the right machine for your needs.

Why Choose Us as Your Rock Crusher Manufacturer

At [Your Company Name], we understand the diverse crushing needs of our clients. Here’s why thousands of customers worldwide trust our rock crushers:

✅ 30+ Years of Manufacturing Experience

✅ Exported to 60+ Countries

✅ ISO & CE Certified Equipment

✅ Custom Solutions for Your Material and Capacity

✅ OEM & ODM Support

✅ Professional Technical Support and After-Sales Service

We design and manufacture rock crushers that meet the demanding needs of mining operations, aggregate producers, construction projects, and recycling businesses. Our machines are engineered for high durability, efficiency, and minimal maintenance.

Our Rock Crusher Product Line

1. Jaw Crusher

Best for: Primary crushing of hard rock, ores, and large stones

A jaw crusher is a compression-based crusher used for primary crushing of large materials. It consists of two jaws — a fixed jaw and a moving jaw — that create a V-shaped chamber to break down materials.

🔧 Key Features:

High crushing ratio (up to 6:1)

Simple structure and easy maintenance

Suitable for hard and abrasive materials

Adjustable discharge size

Ideal for stationary and mobile plants

📊 Technical Parameters:

| Model | Feed Opening (mm) | Max Feed Size (mm) | Capacity (t/h) | Motor Power (kW) | Weight (kg) |

|---|---|---|---|---|---|

| PE250×400 | 250×400 | ≤210 | 5–20 | 15 | 2800 |

| PE600×900 | 600×900 | ≤480 | 50–180 | 55 | 15500 |

| PE900×1200 | 900×1200 | ≤750 | 220–450 | 110 | 50000 |

✅ Applications:

Granite, basalt, quartz, iron ore, limestone, river pebbles

Mining, quarrying, metallurgy, building materials, highways

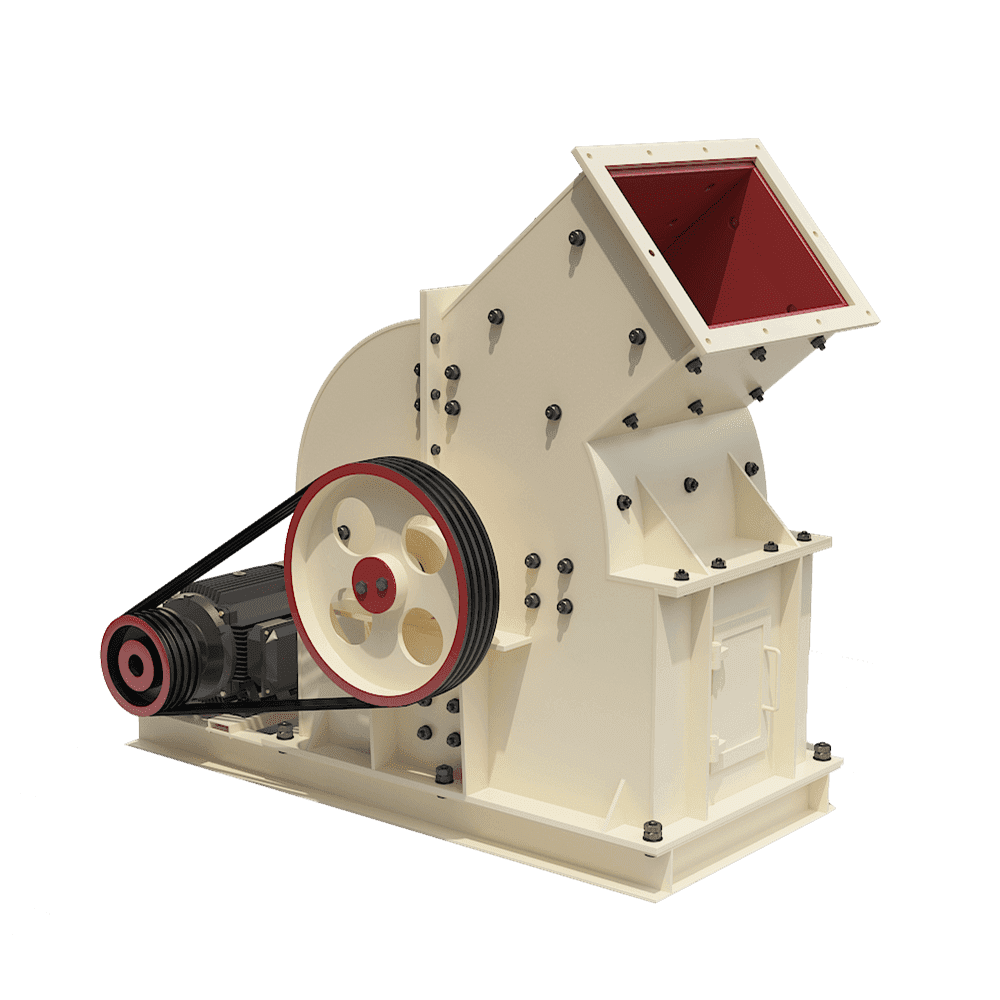

2. Hammer Crusher

Best for: Crushing brittle materials like limestone, coal, gypsum, and clay

The hammer crusher, also known as a hammer mill, uses high-speed rotating hammers to crush materials. It is ideal for medium hardness and less abrasive materials.

🔧 Key Features:

Compact structure

High reduction ratio (up to 25:1)

Easy to operate and maintain

Uniform particle size

Suitable for moist materials (≤15% moisture)

📊 Technical Parameters:

| Model | Feed Size (mm) | Output Size (mm) | Capacity (t/h) | Motor Power (kW) | Weight (kg) |

|---|---|---|---|---|---|

| PC400×300 | ≤100 | 0–10 | 3–8 | 11 | 800 |

| PC800×600 | ≤150 | 0–20 | 20–50 | 55 | 3500 |

| PC1200×1000 | ≤250 | 0–30 | 60–150 | 132 | 11000 |

✅ Applications:

Cement plants, coal processing, brick factories, recycling plants

3. Cone Crusher

Best for: Secondary or tertiary crushing of hard and medium-hard materials

A cone crusher breaks materials by compression between a mantle and a concave liner. It’s ideal for producing finely crushed aggregate and is often used after a jaw crusher.

🔧 Key Features:

High crushing efficiency and capacity

Excellent particle shape

Hydraulic setting adjustment

Overload protection system

Long life of wear parts

📊 Technical Parameters:

| Model | Max Feed Size (mm) | Discharge Range (mm) | Capacity (t/h) | Power (kW) | Weight (kg) |

|---|---|---|---|---|---|

| PYB900 | 115 | 15–50 | 50–90 | 55 | 11200 |

| PYB1200 | 145 | 20–50 | 110–168 | 110 | 19500 |

| HP300 | 200 | 10–45 | 100–250 | 200 | 18700 |

✅ Applications:

Basalt, granite, quartz, iron ore, copper ore

Aggregate plants, sand production lines, mining operations

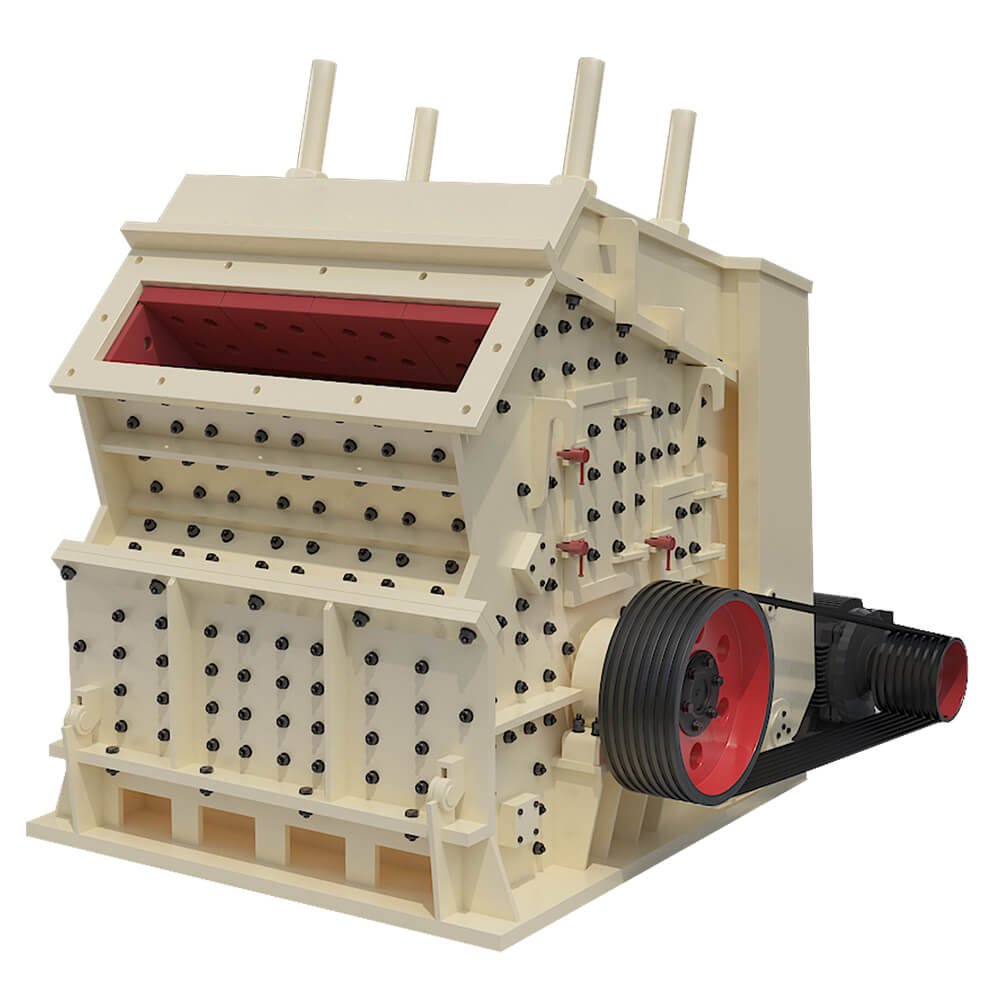

4. Impact Crusher

Best for: Soft to medium-hard materials with cubic output requirements

The impact crusher uses impact force rather than pressure to crush materials. It is widely used in road construction, concrete production, and artificial sand making.

🔧 Key Features:

High reduction ratio

Adjustable discharge size

Excellent grain shape

Low power consumption

Suitable for recycling applications

📊 Technical Parameters:

| Model | Feed Size (mm) | Output Size (mm) | Capacity (t/h) | Motor Power (kW) | Weight (kg) |

|---|---|---|---|---|---|

| PF1007 | ≤300 | 0–60 | 30–50 | 37–55 | 9500 |

| PF1210 | ≤350 | 0–80 | 70–120 | 110 | 15000 |

| PF1315 | ≤500 | 0–90 | 150–280 | 200 | 19500 |

✅ Applications:

Limestone, construction waste, dolomite, shale, concrete

Road building, concrete mixing plants, sand making

Comparison Table of Crusher Types

| Feature | Jaw Crusher | Hammer Crusher | Cone Crusher | Impact Crusher |

|---|---|---|---|---|

| Crushing Method | Compression | Impact + Shear | Compression | High-speed impact |

| Material Hardness | Hard | Medium – Soft | Hard – Medium-hard | Medium |

| Output Shape | Irregular | Fine, Cubical | Cubical | Excellent Cubical |

| Suitable for Moisture | Low | Up to 15% | Low | Medium |

| Reduction Ratio | 6:1 | 10–25:1 | 5:1 | 10–20:1 |

Applications by Industry

| Industry | Recommended Crusher Types |

|---|---|

| Mining | Jaw Crusher, Cone Crusher |

| Construction | Impact Crusher, Hammer Crusher |

| Cement Production | Hammer Crusher, Jaw Crusher |

| Sand Making | Impact Crusher, Cone Crusher |

| Recycling | Impact Crusher, Hammer Crusher |

| Metallurgy | Jaw Crusher, Cone Crusher |

Customer Case Studies

🔹 Limestone Crushing Plant – Saudi Arabia

Equipment: 1x PE900×1200 Jaw Crusher + 2x PC1200×1000 Hammer Crushers

Output: 300 TPH

Purpose: Cement raw material preparation

🔹 Granite Aggregate Line – Peru

Equipment: 1x Jaw Crusher + 1x Cone Crusher + 1x Vibrating Screen

Output: 200 TPH

Application: Construction aggregates

🔹 Recycling Construction Waste – South Africa

Equipment: 1x PF1315 Impact Crusher + Magnetic Separator

Output: 120 TPH

Goal: Produce road base materials

Frequently Asked Questions (FAQ)

Q1: How do I choose the right crusher type?

A: Consider material hardness, feed size, desired output size, capacity, and moisture content. Contact us for a free recommendation.

Q2: Do you offer mobile rock crushers?

A: Yes. We provide mobile jaw crushers, mobile cone crushers, and mobile impact crushers.

Q3: What is your lead time?

A: Standard models are ready in 7–15 days. Custom configurations may take 20–30 days.

Q4: Do you provide installation or on-site support?

A: Yes. We offer remote guidance and can dispatch engineers globally.

After-Sales Service

📞 24/7 Technical Support

📦 Original Spare Parts Supply

🛠 Installation, Commissioning & Training

🔁 Lifetime Service and Maintenance Plans

Contact Us for Your Crushing Equipment Needs

Looking for a reliable rock crusher manufacturer? Get in touch today for a free quotation and customized crushing solution tailored to your business.

📧 Email: john@cementplantpart.com

📞 Phone / WhatsApp: +86 1234567890

🌐 Website: www.cementplantpart.com

🔗 Don’t forget to check our Spare Parts Page and Mobile Crushers Section

Conclusion

Econe is your trusted partner in rock crushing equipment. We are leading rock crusher manufacturer from china. Whether you need a jaw crusher for coarse crushing, a cone crusher for fine aggregates, a hammer crusher for brittle material, or an impact crusher for construction waste, we have the solution.

Our engineering team is ready to help you design, implement, and maintain a complete crushing system — from raw material to finished product.