Main points of the article: Cement plant spare parts management, wear parts supply and service.

Running a cement plant efficiently requires high-quality spare parts to ensure continuous operation and maximum output. Selecting the right spare parts not only minimizes downtime but also reduces maintenance costs. In this article, we’ll explore essential tips for choosing the best cement plant spare parts to enhance performance and ensure long-term success.

1. Understand Your Cement Plant’s Requirements

Every cement plant has unique operational needs depending on its production capacity, equipment specifications, and environmental conditions. Start by conducting a detailed assessment of your plant’s machinery and components. Identify frequently replaced parts such as:

Knowing your specific needs helps you focus on purchasing the most compatible wear parts for maximum plant efficiency.

2. Prioritize Quality and Durability

Durability is crucial when choosing cement plant wear parts. Look for components made from wear-resistant materials like high manganese steel, chromium alloy, or heat-treated alloys. These materials ensure longer service life, reducing the frequency of part replacements.

For example:

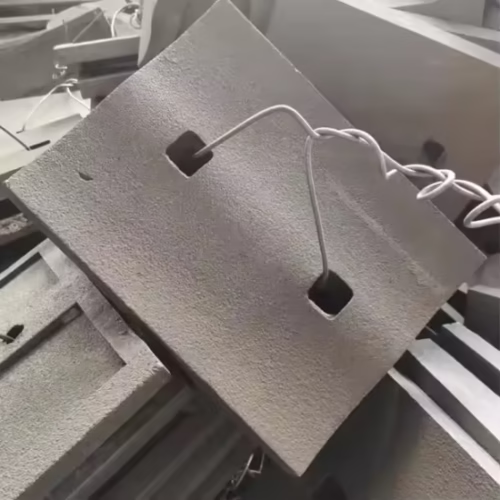

Ball Mill Liners: Opt for liners with excellent wear resistance for prolonged grinding performance.

Crusher Hammers: Choose hammers with high-impact resistance to break down raw materials effectively.

3. Choose Reliable Cement Plant Spare Parts Suppliers

Partnering with reputable suppliers ensures the quality and reliability of your spare parts supply. A trustworthy supplier should offer:

Consistent Product Quality: Verified by customer reviews and certifications.

On-Time Delivery: To minimize production delays.

After-Sales Support: Including technical assistance and maintenance advice.

4. Focus on Compatibility and Customization

Spare parts must be fully compatible with your plant’s existing machinery. Before purchasing, verify the specifications, dimensions, and installation requirements. Custom-made spare parts are ideal if your plant has non-standard equipment or unique process requirements.

5. Consider Inventory Management

Maintaining an optimal inventory of critical spare parts prevents unexpected production halts. Use a preventive maintenance schedule to predict when parts need replacement and stock up accordingly.

6. Evaluate Cost vs. Value

While lower-priced spare parts might seem cost-effective initially, they may result in frequent breakdowns and higher long-term expenses. Instead, invest in high-quality parts with proven performance records to reduce maintenance costs and maximize plant output.

7. Embrace Technological Advancements

Modern cement plant spare parts often feature advanced designs that improve operational efficiency. Look for components with innovations like improved wear patterns, energy-saving capabilities, and reduced friction for better overall performance.

Conclusion

Selecting the right cement plant spare parts is essential for maximizing output, reducing maintenance costs, and ensuring long-term operational success. By understanding your plant’s needs, prioritizing quality, working with reliable suppliers, and managing spare part inventory effectively, you can enhance the overall efficiency of your cement manufacturing process.

Arki Cement offers a wide range of high-quality spare parts supply for cement plants, including ball mill liners, crusher hammers, and more. Contact us today for expert guidance and premium spare parts designed to meet your plant’s unique requirements.

Keywords: Cement Plant Spare Parts supply, High-Quality Cement Wear Parts, Crusher Hammers, Ball Mill Liners, Cement Equipment Components, Cement Plant Maintenance, Spare Parts Supplier, Durable Cement Plant Parts, Reliable Cement Plant Machinery, Custom Cement Plant Part.