Cuando se trata del rendimiento y la durabilidad de los equipos de trituración, la calidad de las piezas de desgaste -especialmente los martillos trituradores- es fundamental. Como líder Proveedor chino de martillos trituradores de aleaciónLtd., nos especializamos en la fabricación y el suministro de martillos trituradores de acero aleado de primera calidad para diversas aplicaciones, como la minería, la producción de cemento, la metalurgia y las industrias de agregados. En este artículo en profundidad, exploraremos las ventajas de los martillos trituradores de aleación, nuestras capacidades de fabricación, los estándares de calidad, la gama de productos, la cadena de suministro global y las razones para elegirnos como su socio a largo plazo.

1. Introducción a los martillos trituradores

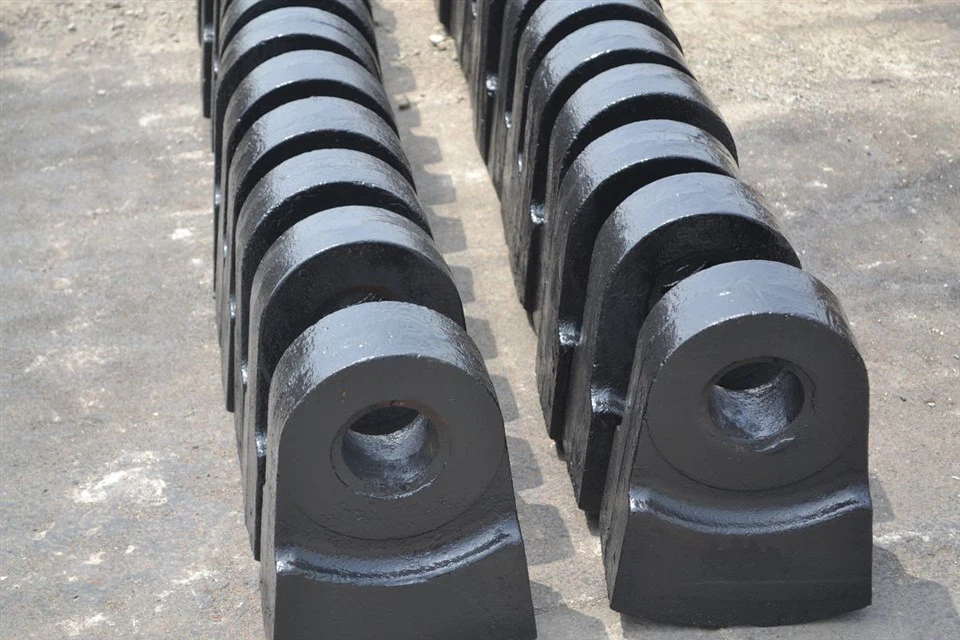

Los martillos trituradores son componentes esenciales de las trituradoras de martillos. Se encargan de propinar golpes de gran impacto para triturar materiales como piedra caliza, carbón, clinker, granito, basalto y mineral de hierro. En función de las materias primas y las condiciones de funcionamiento, los martillos de las trituradoras sufren un gran desgaste, abrasión y tensión por impacto.

Para garantizar la máxima productividad y rentabilidad, los fabricantes necesitan martillos trituradores fabricados con materiales resistentes al desgaste y a los impactos. El acero aleado es una de las mejores opciones para este fin.

2. ¿Por qué elegir martillos trituradores de acero aleado?

Los martillos trituradores de acero aleado están diseñados para ofrecer un rendimiento superior en entornos de alto desgaste. Estas son sus principales ventajas:

Mayor resistencia al desgaste: Elementos de aleación como el cromo (Cr), el manganeso (Mn), el molibdeno (Mo) y el níquel (Ni) mejoran la resistencia al desgaste, prolongando la vida útil.

Resistencia mejorada: Los martillos de aleación ofrecen una excelente resistencia al impacto, reduciendo el riesgo de agrietamiento o rotura.

Alta dureza: El tratamiento térmico y los elementos de aleación mejoran la dureza superficial manteniendo la tenacidad del núcleo.

Composición personalizable: La composición química puede adaptarse a las necesidades específicas de cada aplicación.

Ahorro de costes: La mayor vida útil y el menor número de sustituciones reducen los costes de mantenimiento y los tiempos de inactividad.

3. Nuestras capacidades de fabricación

Como empresa de confianza Proveedor chino de martillos trituradores de aleaciónOfrecemos soluciones integrales de fabricación:

3.1 Selección de materias primas

Nos abastecemos de tochos de acero aleado de alta calidad y controlamos cuidadosamente su composición química para garantizar una calidad constante.

3.2 Procesos de producción avanzados

Métodos de fundición: Fundición en arena, fundición a la espuma perdida y fundición de precisión.

Tratamiento térmico: Normalizado, temple, revenido y endurecimiento superficial para optimizar las propiedades mecánicas.

Mecanizado: El mecanizado CNC garantiza la precisión dimensional y un ajuste perfecto.

3.3 Sistema de control de calidad

Análisis químico con espectrómetros.

Pruebas de dureza (Brinell, Rockwell).

Pruebas de resistencia al impacto.

Inspección dimensional y visual.

Contamos con la certificación ISO 9001 y todos nuestros productos cumplen las normas internacionales.

4. Gama de productos y aplicaciones

Suministramos martillos trituradores de aleación para diversos tipos de trituradoras e industrias:

4.1 Tipos de trituradoras

Trituradora de martillos

Trituradora de impacto

Trituradora de martillos reversible

Trituradora de martillos anulares

4.2 Materiales que trituramos

Piedra caliza

Carbón

Clinker

Mineral de hierro

Granito

Basalto

4.3 Sectores atendidos

Cementeras

Explotaciones mineras

Canteras de áridos

Centrales eléctricas

Instalaciones metalúrgicas

4.4 Calidades populares de aleación

Acero con alto contenido en manganeso (Mn13, Mn13Cr2, Mn18Cr2)

Hierro con alto contenido en cromo

Martillos bimetálicos compuestos (acero aleado + alto contenido en cromo)

Acero martensítico

5. Servicios de personalización y OEM

Ofrecemos servicios OEM y ODM para satisfacer las necesidades específicas de los clientes:

Tamaños y formas personalizados

Composiciones de aleación personalizadas

Grabado de marcas y números de pieza

Dibujo técnico y desarrollo de muestras

Nuestro equipo de I+D colabora estrechamente con los clientes para ofrecer soluciones a medida basadas en las condiciones de trabajo y el rendimiento requerido.

6. Exportación global y apoyo logístico

Como profesional Proveedor chino de martillos trituradores de aleaciónTenemos años de experiencia en comercio internacional. Exportamos a más de 30 países, incluyendo:

Vietnam

Indonesia

Turquía

Sudáfrica

Egipto

Pakistán

Rusia

Brasil

6.1 Opciones de envío

FOB China Puertos Principales (Shanghai, Qingdao, Ningbo)

CIF al puerto de destino

DDP para los países seleccionados

6.2 Embalaje

Cajas de madera

Palés de acero

Embalaje con logotipo personalizado

7. ¿Por qué elegirnos como proveedor de martillos trituradores de aleación?

7.1 Precio directo de fábrica

Ofrecemos precios competitivos sin comprometer la calidad.

7.2 Entrega rápida

La disponibilidad de existencias y la eficacia de las líneas de producción garantizan una rápida tramitación de los pedidos.

7.3 Asistencia técnica

Ingenieros experimentados prestan asistencia desde la selección hasta la instalación.

7.4 Antecedentes probados

Miles de proyectos con éxito en todo el mundo.

7.5 Excelente servicio posventa

Proporcionamos orientación para la instalación, análisis del rendimiento y planificación de la sustitución.

8. Casos prácticos y testimonios de clientes

8.1 Fábricas de cemento en Pakistán

Suministramos martillos de aleación de alto manganeso que duraban 2,5 veces más que los modelos anteriores.

8.2 Explotación de minas de carbón en Sudáfrica

Nuestros martillos trituradores bimetálicos compuestos redujeron el tiempo de inactividad en 40%, aumentando la productividad.

8.3 Canteras de granito en Rusia

Los martillos de acero martensítico superaron con éxito condiciones extremas de impacto y abrasión.

9. Preguntas más frecuentes (FAQ)

P1: ¿Pueden diseñar martillos trituradores a partir de nuestros planos? Sí, admitimos diseños personalizados e ingeniería inversa a partir de muestras o dibujos técnicos.

P2: ¿Cómo garantizan la dureza y tenacidad de los martillos? Utilizamos procesos precisos de tratamiento térmico y estrictas medidas de control de calidad.

P3: ¿Cuál es el plazo de entrega habitual de los pedidos? El plazo de entrega estándar es de 15-30 días, dependiendo de la cantidad del pedido.

P4: ¿Ofrecen pedidos de prueba? Sí, aceptamos pedidos de prueba para comprobar el rendimiento de nuestros productos.

P5: ¿Qué condiciones de pago aceptan? T/T, L/C, y otros términos flexibles pueden ser negociados.

10. Póngase en contacto con el proveedor líder de martillos trituradores de aleación de China

Si busca martillos trituradores de aleación fiables, duraderos y rentables, somos su mejor socio. Como empresa Proveedor chino de martillos trituradores de aleaciónCombinamos excelencia en la fabricación, logística global y experiencia técnica para respaldar sus operaciones de trituración.

Póngase en contacto con nosotros hoy mismo:

Correo electrónico: john@cementplantpart.com

WhatsApp: +86-15057941949

Página web: www.cementplantpart.com