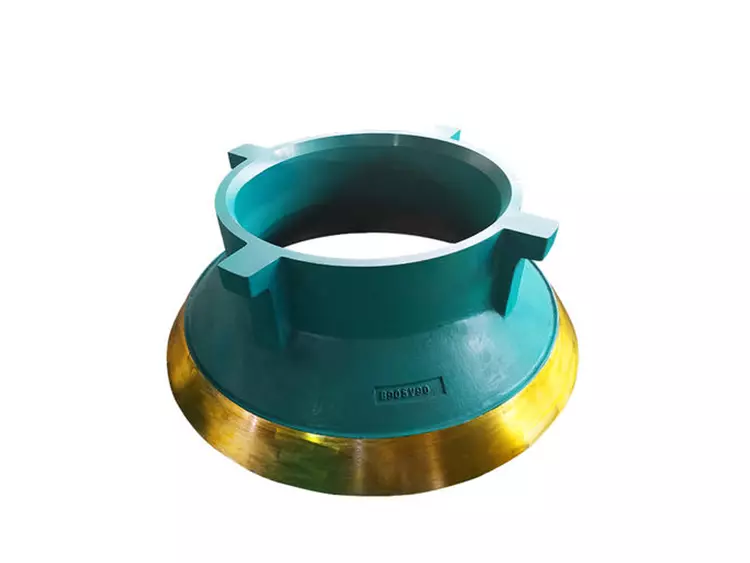

High-Quality Cone Crusher Bowl Liner – Superior Durability and Performance

- Material: High Manganese Steel (Mn13, Mn18, Mn22) or Alloy Steel

- Hardness: 48-55 HRC (heat-treated for enhanced durability)

- Profiles: Standard, Medium, Short Head

- Compatibility: Fits various cone crusher models (Metso, Sandvik, Terex, etc.)

- Weight Range: 500 kg to 2,000 kg (customizable based on crusher type)

- Applications: Mining, aggregate, cement, recycling, and more

High-Quality Cone Crusher Bowl Liner – Superior Durability and Performance

Introduction:

Our Cone Crusher Bowl Liners are engineered for optimal performance and durability in crushing applications. Manufactured using premium wear-resistant materials, these liners provide excellent protection for the crusher bowl, ensuring long-lasting service life. Designed to fit a wide range of cone crusher models, they are ideal for mining, quarrying, and aggregate production applications.

Key Features of Cone Crusher Bowl Liner

Premium Wear-Resistant Material:

Made from high manganese steel or alloy steel, our bowl liners deliver exceptional impact resistance and wear life, ensuring prolonged durability even under the toughest crushing conditions.Precision Fit for Maximum Efficiency:

Each bowl liner is precision-engineered to ensure a perfect fit with your cone crusher model, enhancing overall crushing efficiency and reducing energy consumption.Optimized Crushing Performance:

With a design tailored for superior material flow and consistent product size, our bowl liners ensure smooth crushing operations and better output quality.Customizable Options:

Available in a variety of profiles (standard, medium, and short head), our bowl liners are customizable to suit different crushing applications and material types.Easy Installation and Replacement:

Designed for quick installation, our liners reduce downtime and maintenance costs, ensuring uninterrupted production.

Applications of Cone Crusher Bowl Liner

Mining Industry:

Suitable for crushing ores such as iron, copper, gold, and other minerals, ensuring high throughput and consistent product quality.Quarrying:

Widely used for crushing hard stones like granite, basalt, and limestone in quarry operations, delivering superior performance.Aggregate Production:

Essential for producing high-quality aggregates for construction, road building, and concrete manufacturing.Cement Industry:

Ideal for processing raw materials in cement plants, including limestone, shale, and other aggregates.Recycling Operations:

Effective for crushing recycled materials like concrete, asphalt, and other construction debris.

Technical Specifications

- Material: High Manganese Steel (Mn13, Mn18, Mn22) or Alloy Steel

- Hardness: 48-55 HRC (heat-treated for enhanced durability)

- Profiles: Standard, Medium, Short Head

- Compatibility: Fits various cone crusher models (Metso, Sandvik, Terex, etc.)

- Weight Range: 500 kg to 2,000 kg (customizable based on crusher type)

- Applications: Mining, aggregate, cement, recycling, and more

- MOQ: Contact us for details

- Delivery Time: 10-15 days after order confirmation

Advantages of Our Cone Crusher Bowl Liners

Extended Wear Life:

Advanced materials and precision manufacturing extend the wear life, reducing downtime and replacement frequency.Enhanced Crusher Efficiency:

Perfect fit and optimized profiles improve crushing efficiency, ensuring consistent product quality and higher productivity.Lower Maintenance Costs:

Durable design and easy installation reduce maintenance efforts and operational costs.Versatility:

Customizable options and compatibility with multiple crusher models make our bowl liners suitable for a wide range of applications.Reliable Performance:

Proven in demanding environments, our bowl liners deliver consistent performance and excellent wear resistance.

Why Choose Our Cone Crusher Bowl Liners?

Expert Manufacturing:

Produced using state-of-the-art technology and stringent quality control processes.Trusted by Professionals:

Widely used by leading mining and quarrying companies globally.Competitive Pricing:

High-quality liners at factory-direct prices ensure excellent value for money.Comprehensive Support:

Our experienced team provides guidance on selection, installation, and maintenance.

FAQs About Cone Crusher Bowl Liners

What materials are your bowl liners made from?

We use high manganese steel (Mn13, Mn18, Mn22) and alloy steel for exceptional wear resistance and durability.Do you offer liners for specific cone crusher models?

Yes, we offer liners compatible with popular models from Metso, Sandvik, Terex, and other brands.Can I customize the profile of the bowl liner?

Absolutely! We provide standard, medium, and short head profiles to meet your specific crushing requirements.What is the average lifespan of your bowl liners?

Lifespan varies depending on the material being crushed, but our liners are designed for maximum durability and performance.

Order Your Cone Crusher Bowl Liners Today

Enhance your crushing operations with our durable and efficient Cone Crusher Bowl Liners. Contact us now for a free quote or more information on how our products can improve your crushing productivity and reduce costs.

Conclusion

Our Cone Crusher Bowl Liners are the perfect solution for ensuring efficient and reliable crushing in demanding applications. Designed for durability, performance, and compatibility, they are a cost-effective choice for mining, quarrying, and aggregate production industries.