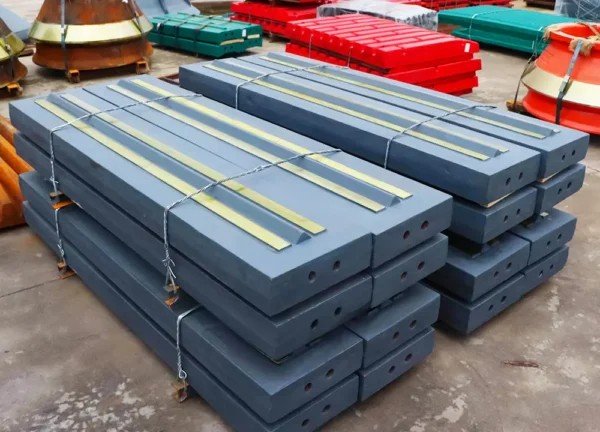

High Manganese Steel Crusher Hammer for Impact Crushers

Specification for High Manganese Steel Crusher Hammer for Impact Crushers

- Material: High Manganese Steel (Mn13, Mn13Cr2, Mn18Cr2, Mn22Cr2)

- Hardness: HRC 50-60 (Self-hardening upon impact)

- Application: Impact Crushers for mining, cement, aggregates, and recycling

- Customization: Available in different sizes and shapes for specific crusher models

Product Overview

The High Manganese Steel Crusher Hammer for Impact Crushers is an essential wear-resistant component designed to withstand extreme impact forces and abrasive materials. Manufactured from premium high manganese steel (Mn13, Mn13Cr2, Mn18, Mn18Cr2, Mn22Cr2), this hammer offers superior durability, high impact resistance, and an extended service life.

Widely used in mining, cement plants, aggregate production, and recycling industries, this impact crusher hammer delivers optimized crushing performance, reduced downtime, and lower maintenance costs. Our precision-engineered hammers ensure higher crushing efficiency and better material fragmentation, making them the ideal choice for impact crushers.

Key Features of High Manganese Steel Crusher Hammer for Impact Crushers

1. High-Quality Manganese Steel Composition

- Made from Mn13, Mn13Cr2, Mn18, Mn18Cr2, Mn22Cr2, ensuring excellent wear resistance.

- Self-hardening under impact, increasing hardness and durability during operation.

- High toughness prevents breakage and ensures long-lasting performance.

2. Exceptional Impact Resistance

- Designed to withstand high-speed impacts and extreme crushing forces.

- Maintains structural integrity even under the toughest working conditions.

- Minimizes premature wear and extends the lifespan of the impact crusher.

3. Superior Wear Resistance & Extended Service Life

- High manganese steel material ensures longer wear life, reducing the need for frequent replacements.

- Perfectly suited for crushing abrasive and hard materials such as granite, limestone, and iron ore.

- Reduces downtime and overall operational costs.

4. Optimized Crushing Efficiency

- Enhances the crusher’s performance by ensuring uniform impact force distribution.

- Prevents material clogging and ensures smooth crushing operations.

- Boosts overall productivity and efficiency in crushing plants.

5. Customizable Sizes & Designs

- Available in various sizes, thicknesses, and weights to fit different impact crusher models.

- OEM and customized designs based on specific crusher requirements.

- Compatible with leading impact crusher brands.

6. Easy Installation & Maintenance

- Precision-manufactured to ensure a perfect fit in impact crushers.

- Reduces installation time and simplifies maintenance procedures.

- Requires minimal maintenance, lowering overall operational expenses.

Applications of High Manganese Steel Crusher Hammer

1. Mining Industry

- Used in impact crushers for breaking down hard ores and rocks.

- Ideal for primary and secondary crushing in mining operations.

2. Cement Plants

- Essential in crushing limestone, clay, and raw materials for cement production.

- Ensures consistent material processing for high-quality cement manufacturing.

3. Aggregate Production

- Designed for crushing gravel, sand, and construction aggregates.

- Enhances efficiency in aggregate and road construction applications.

4. Recycling Industry

- Perfect for crushing concrete, asphalt, and demolition waste.

- Helps in reducing waste and promotes sustainable material recycling.

Technical Specifications of Crusher Hammer for Impact Crushers

| Specification | Details |

|---|---|

| Material | High Manganese Steel (Mn13, Mn13Cr2, Mn18, Mn18Cr2, Mn22Cr2) |

| Hardness | HRC 50-60 (Self-hardens upon impact) |

| Impact Strength | High toughness & wear resistance |

| Application | Impact Crushers for mining, cement, aggregate, and recycling |

| Customization | OEM sizes & designs available for different crusher models |

| Service Life | Extended durability compared to standard steel hammers |

Advantages of Our High Manganese Steel Crusher Hammer

✅ Exceptional Durability – Hardens under impact, increasing resistance to wear and breakage.

✅ High Crushing Efficiency – Delivers superior performance in impact crushers.

✅ Reduced Downtime – Less frequent replacements lower operational costs.

✅ Custom Fit for Various Crushers – Available for different brands and models.

✅ Cost-Effective Solution – Optimized durability reduces maintenance expenses.

FAQs About High Manganese Steel Crusher Hammer for Impact Crushers

❓ What makes high manganese steel ideal for impact crusher hammers?

✔ High manganese steel has self-hardening properties, making it highly impact-resistant and durable, ideal for crushing hard and abrasive materials.

❓ How long does a manganese crusher hammer last?

✔ Service life depends on the material being crushed, but high manganese steel significantly extends wear life compared to standard steel.

❓ Can crusher hammers be customized?

✔ Yes! We offer customized sizes, thicknesses, and designs to fit specific impact crusher models and applications.

❓ What materials can this hammer crush?

✔ Suitable for limestone, granite, iron ore, concrete, asphalt, and other high-impact materials.

❓ How do I install the crusher hammer?

✔ Our hammers are precision-manufactured for a perfect fit and easy installation, reducing downtime.

Order Your High Manganese Steel Crusher Hammer Today!

Upgrade your impact crusher with our high-quality manganese steel hammers for superior durability, crushing efficiency, and cost-effectiveness. Contact us now for a custom quote and improve your crusher’s performance!

📞 Contact Us Now for a Free Quote!