Crusher Wear Parts Manufacturer - Replacement Spare Part

Replacement Crusher Wear Parts Manufacturer – High Quality Crusher Spare Parts Supplier From China.

Provide replacement parts for Jaw Crusher , hammer crusher, cone crusher, impact crusher.

Why Choose Our Crusher Wear Parts?

At Econe, as a leading crusher wear parts supplier from China, we provide high-quality crusher spare parts and wear parts designed for durability and efficiency. Our products cater to various industries, ensuring that your crushing equipment operates at its peak performance.

- Premium Materials: Manufactured with robust materials to withstand extreme conditions.

- Precise Fit: Tailored to match your specific crusher models.

- Global Shipping: Reliable delivery to customers worldwide.

- Expert Support: Technical assistance from experienced professionals.

Range of Crusher Parts

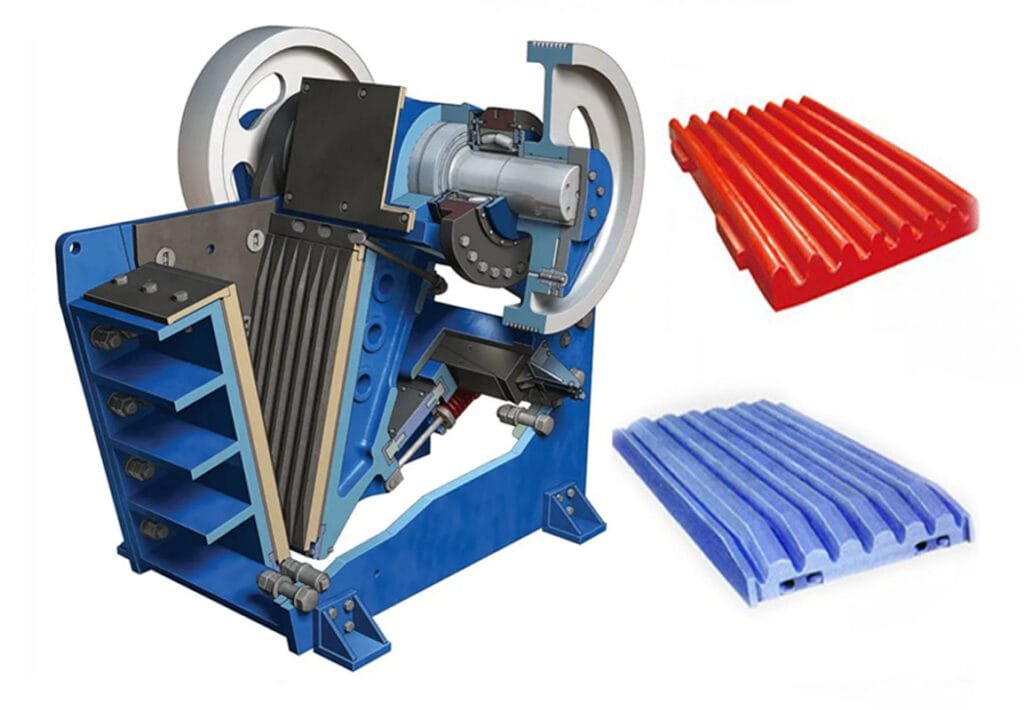

- Jaw Crusher Spare Part

We specialize in providing high-quality jaw crusher spare parts designed to deliver exceptional wear resistance, prolonged service life, and reliable performance under the most demanding crushing conditions.

Our Jaw Crusher Parts include Jaw Plates, Toggle Plate and Ecentric shaft.

High Quality Materials for your options: High Manganese steel (Mn13Cr2, Mn18Cr2), Chromium Steel (Cr15, Cr20, Cr26), Alloy Steel (ZGCr5Mo, ZGCr15)

Whether you are operating in the mining, quarrying, cement, or recycling industries, our replacement parts are manufactured to meet or exceed OEM standards to ensure seamless compatibility and efficient operation.

- Hammer Crusher Spare Part

We provide high quality Hammer crusher wear parts such as Crusher hammers and Screen Plate with High Quality Materials for your options

Super Quality Materials: High Manganese steel (Mn13Cr2, Mn18Cr2), Chromium Steel (Cr15, Cr20, Cr26), Alloy Steel (ZGCr5Mo, ZGCr15)

Hardness: 45-65 HRC (Rockwell hardness scale)

- Cone Crusher Spare Part

Cone Crusher Bowl Liner Technical Specifications

- Material: High Manganese Steel (Mn13, Mn18, Mn22) or Alloy Steel

- Hardness: 48-55 HRC (heat-treated for enhanced durability)

- Profiles: Standard, Medium, Short Head

- Compatibility: Fits various cone crusher models (Metso, Sandvik, Terex, etc.)

- Weight Range: 500 kg to 2,000 kg (customizable based on crusher type)

- Applications: Mining, aggregate, cement, recycling, and more

Cone Crusher Mantle and Concave – High Quality Wear Parts Supplier

- Material Options: High Manganese Steel (Mn13Cr2, Mn18Cr2, Mn22Cr2), High Chromium Steel, Alloy Steel

- Hardness: HRC 50-60 (heat-treated for superior wear resistance)

- Profiles: Standard, Medium, and Short Head concave profiles available

- Compatible Crushers: Suitable for cone crusher models from Sandvik, Metso, Terex, and other major brands

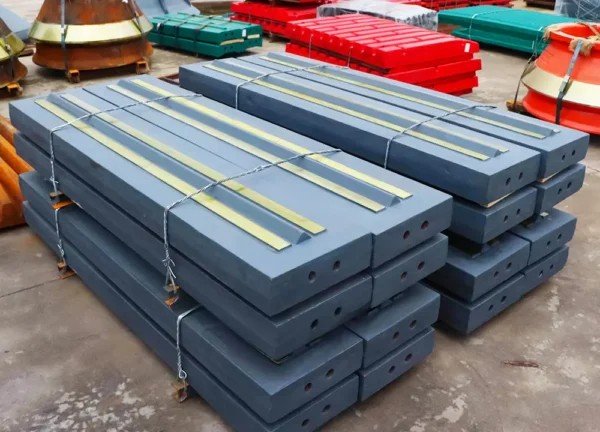

- Impact Crusher Spare Part

Specification for Impact Crusher Blow Bars – Wear Parts Manufacturer

- Material: High Manganese Steel (Mn13, Mn18Cr2), High Chromium Cast Iron (Cr15, Cr20, Cr26), Alloy Steel (ZG40CrMo, ZG45Mn)

- Hardness: 45-65 HRC (Rockwell hardness scale)

- Weight: 5 kg – 500 kg (customized based on the crusher size)

- Applications: Designed to fit most impact crusher models used in mining, aggregate, and recycling industries. Suitable for crushing a variety of materials, including limestone, granite, concrete, and asphalt.

- Customizable: Yes, Blow bars can be customized in terms of size, material composition, and design to fit specific customer requirements.

Specification for High Manganese Steel Crusher Hammer for Impact Crushers

- Material: High Manganese Steel (Mn13, Mn13Cr2, Mn18Cr2, Mn22Cr2)

- Hardness: HRC 50-60 (Self-hardening upon impact)

- Application: Impact Crushers for mining, cement, aggregates, and recycling

- Customization: Available in different sizes and shapes for specific crusher models

Crusher Wear Parts | High-Quality Replacement & Spare Parts

Welcome to our Crusher Wear Part category! We specialize in providing durable and reliable solutions for your crushing needs. Our products are engineered to deliver exceptional performance and extended lifespan, ensuring optimal production efficiency.

Product Highlights

- Crusher Wear Parts: High-strength components designed to withstand extreme conditions and reduce downtime.

- Crusher Replacement Parts: Perfect fit for replacing worn or damaged parts, maintaining peak operational efficiency.

- Crusher Spare Parts: A comprehensive range of spare parts to keep your crushers running smoothly.

The Importance of Quality Crusher Part

Using genuine crusher parts is essential to maintaining the efficiency and productivity of your crushing equipment. Our crusher parts are designed with the following benefits:

- Extended Equipment Life: Our high-quality parts ensure that your crushers operate at peak performance for longer periods, reducing downtime and increasing productivity.

- Improved Efficiency: Parts that fit perfectly and are engineered to your machine’s specifications reduce friction and wear, ensuring more efficient crushing operations.

- Minimized Maintenance Costs: With our durable parts, you can avoid costly repairs and replacements, saving you money over the long term.

Applications

Our products are suitable for a wide range of industries, including mining, quarrying, cement plants, and recycling.

Frequently Asked Questions (FAQs)

1. What types of crusher spare parts do you offer?

We provide parts for jaw crushers, cone crushers, impact crushers, hammer crushers, and VSI crushers.

2. Are your parts compatible with all crusher brands?

Yes, we manufacture parts compatible with leading crusher brands.

3. How can I ensure the correct fit for my crusher?

Our technical team is available to help you choose the right parts for your equipment.

For inquiries or a free consultation, please contact us. We are committed to providing the best Crusher Wear Parts, Replacement Parts, and Spare Parts to meet your specific requirements.

How to Buy Cheap Cone Crusher Wear Parts for Your Cone Crusher